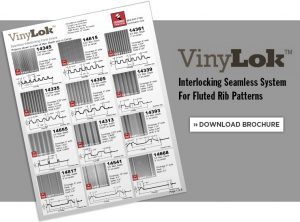

VinyLok™ Seamless Interlocking Extruded-Plastic Form Liners

VinyLok form liners are extruded in lengths of up to 40 feet for use in tilt-up, precast, and cast-in-place concrete applications. Their unique interlocking system provides the ideal solution for projects where seamless finishes are required.

VinyLok form liners are extruded in lengths of up to 40 feet for use in tilt-up, precast, and cast-in-place concrete applications. Their unique interlocking system provides the ideal solution for projects where seamless finishes are required.

Benefits:

- Seamless finishes

- Design flexibility

- Fast installation

- Reduced labor costs

- Less concrete leakage, grinding, sacking or patching

- Installation is a Snap

VinyLok comes with an interlocking nailing strip, which is designed so the contractor may fasten the liner to his substrate and lock the rib over top of the fastener. This feature gives the form liner higher re-use and assures a clean concrete finish with no unsightly nail head impressions or grooves. In addition, VinyLok is manufactured from Acrylonitrile-Butadiene Styrene (ABS) — a plastic that has exceptional strength and resiliency, yet is easily cut with hand or power tools.

Design Versatility

VinyLok is available in a wide range of standard patterns and has the ability to reproduce almost any smooth fluted linear design. Custom patterns are also welcome.

Economy

The quick installation time, together with up to 10 re-uses, minimizes the cost per square foot of material.

Prevents Leakage

VinyLok’s special interlocking system prevents concrete leakage and virtually eliminates the need for grinding or sacking/patching.

Dimensions

Standard panel lengths from 3 feet to 40 feet are available — eliminating the need to purchase oversized form liners, which may add to material and labor costs.